Boat Maintenance can be intimidating for those of us who have never done it before.

Who does their own and who wants to learn? What advice can you give someone who’s new to boat motor maintenance?

Today, with the help of someone who is meticulous and detail oriented, I did my very first boat motor service ever.

Thanks to all the YouTubers who made videos on motor oil changes and gear lube oil changes, I was able to follow along and understand what we were doing today.

Hopefully, overtime, I will also learn how to fix other things on my boat motor as I believe knowing how to service and fix your boat can help get you back to the launch if something should fail while on a fishing trip. Knowing how to do a simple service will also save money overtime and this is important as well because it will help keep more disposable income in my pocket to buy more fishing gear. ![]()

For those of you who are interested in learning how to do a boat motor service, I highly recommend finding someone who has done one before. It helped having someone show me for the first time, because it took some doubt out of the equation. Thankfully, everything we did was what I would have done if I was on my own, except it took a fraction of the time.

The process was so simple that I’m amazed I haven’t tried doing it on my own before. Half of the reason I have never done a motor service on my own is because I have always preferred to pay someone who knows what they are doing and the other half of the reason is procrastination and the intimidation factor of having not grown up doing mechanical work at home.

We started by placing my motor in a large garbage can, because my motor’s water intake is under the fin on the leg. Good thing I didn’t buy water muffs for my 15hp Mercury outboard motor. We started the motor and ran it for at least 15 minutes. Then we lifted it up and turned it to the oil drain plug side. The drain pan was on the ground and our aim was not as good as it could have been. Upon taking out the oil drain plug, oil shot out past the edge of the drain pan and over onto the concrete pad we were working on. Thankfully, a few paper towels and some wax and grease remover did the trick to cleaning up the mess and not staining the concrete. Next, after the oil had a chance to drain out of the motor, we plugged the drain hole and lowered the motor for a few minutes to allow more oil to drain into the bottom cavity of the oil compartment. We lifted the motor again and opened the drain plug. I was amazed at how much more oil came out. One thing I learned, was this oil drain pan had a spout in it to allow you to pour it into a container to take to the recycling depot.

With the oil drain plug open, we started removing the oil filter. The filter came off effortlessly and a small amount of oil on the new oil filter seal helped seal it in place on the motor. We hand tightened the oil filter onto the motor three quarters to one full turn after it became snug on the initial tightening.

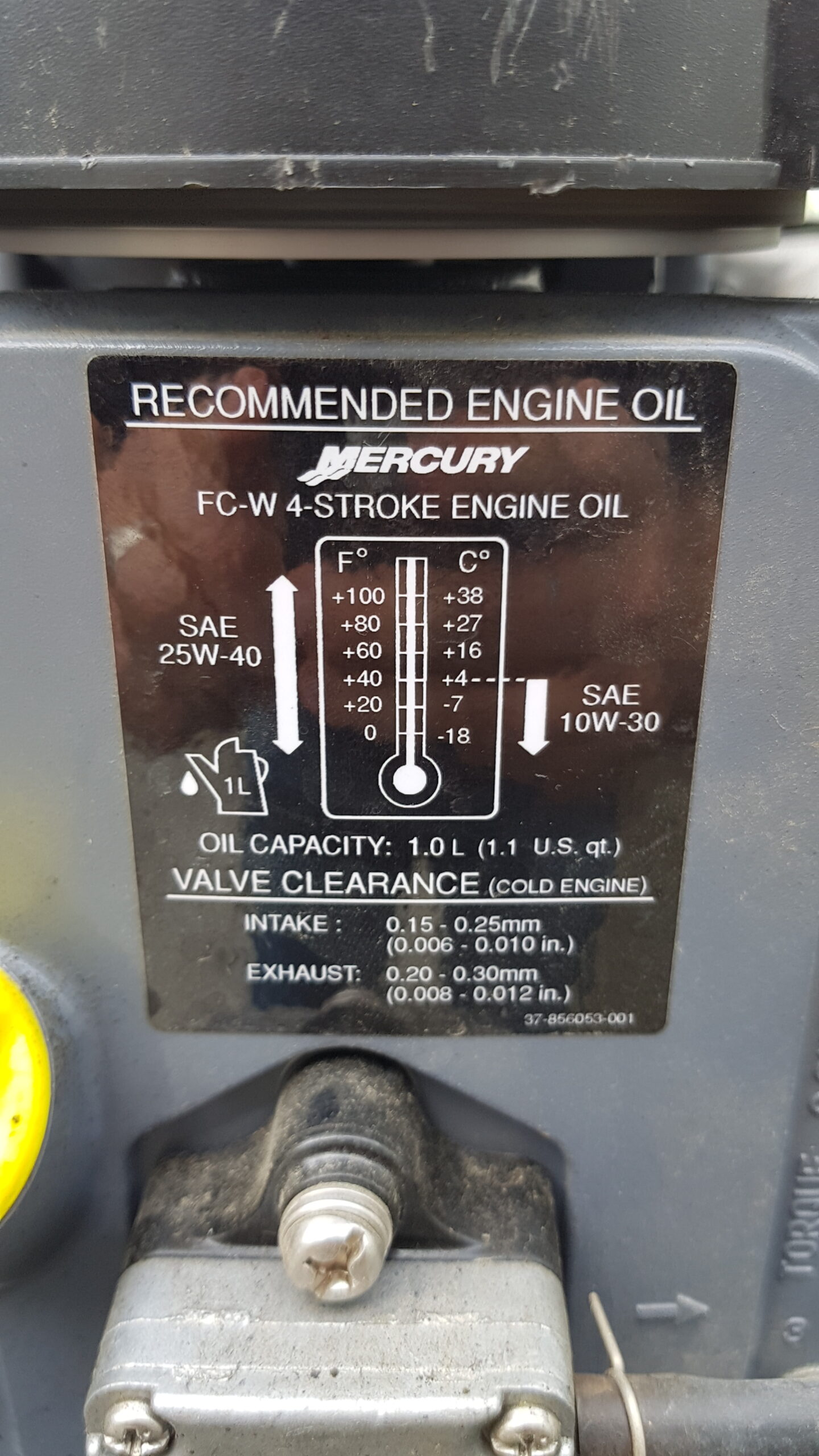

At this point, all was going exactly the way I wanted it to. YouTube was my friend and I understood every step up to this point. We put the drain plug back in and poured the recommended amount of oil into the motor (which was clearly marked on the motor itself). A quick dipstick check proved it to be a “perfect pour” and just above the full mark which would be down to the full level after the oil filter filled up on the initial run to the lake.

The leg gear lube was easy to change as well. Just like on YouTube, the gear lube is drained by opening the lower plug first and then the top. While draining this we need to watch for a milky consistency which we beleive my motor had. I’ll be looking into what is needed to fix this later. The hand pump I purchased from NR motors in Prince George did what it does and we filled the lower leg with gear lube. As soon as the lube started coming out of the top hole, we plugged the top hole. Then a few more pumps of gear lube and then we plugged the lower hole. It was that simple!

As for other maintenance, we changed the fuel filter and checked the spark plugs. I learned how easy it is to check spark plugs with a feeler gauge. One of my spark plugs was out a bit according to the motors specifications labeled on the motor itself. A helpful tip for changing new spark plugs was a story and lesson to always use your feeler gauge to check new spark plugs, because sometimes they are out even when new. Lastly, we took the prop off to check for fishing line stuck in the prop which can be bad for your seals. We did this by sticking a 2×4 between the motor and the prop and took it off with a socket wrench. We lubed up the prop shaft with lube and put it all back together.

All in all, doing a complete motor service was a great learning experience today. I’m hoping we didn’t miss anything. This afternoon, I took the boat to Dragon Lake to test it out and enjoy the sun. I have to say, I’m completely satisfied that I was able to learn and happy we did the service ourselves. My motor actually runs better now because of this simple preventative maintenance schedule that I’ll be doing on my own from now.